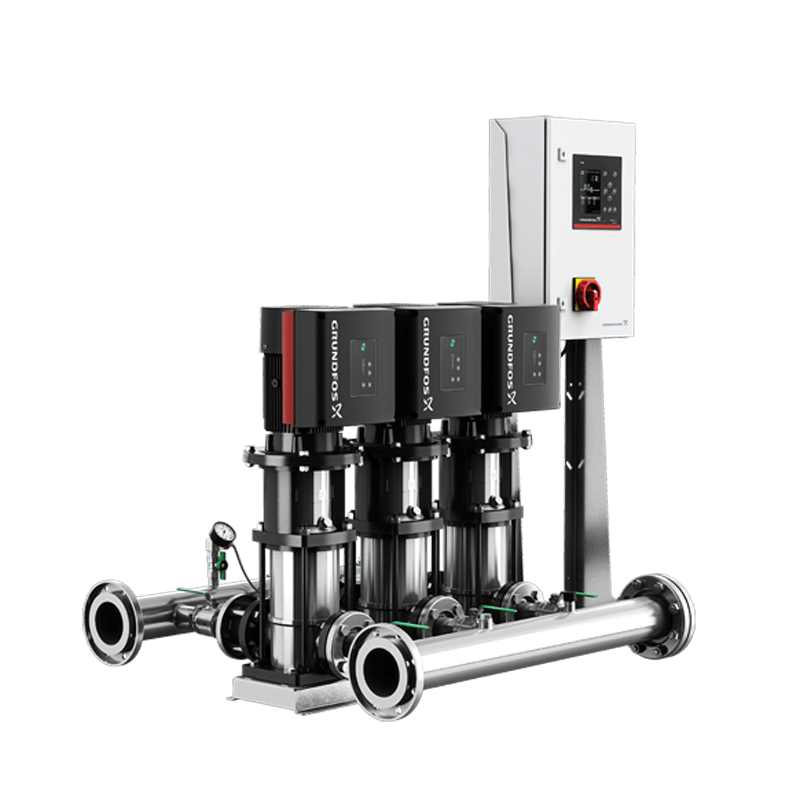

Grundfos MPC 3 pump booster sets 3ph

Grundfos Hydro MPC-E 3 CRIE5-9 98426918 IE5 400v

In stock

- Established 1975

- Trusted by thousands of customers

Grundfos Hydro MPC-E 3 CRIE5-9 98426918 IE5 400v

Pressure booster system supplied as compact assembly according to DIN standard 1988/T5.

All pumps are speed-controlled.

From 0.37 to 11 kW, the booster system is equipped with CR, CRE, CRI, CRIE pumps with electronically commutated permanent-magnet motors with extremely high efficiency. The total efficiency of the motor including the frequency converter applies to IE5 level in IEC60034-31.

From 15 to 22 kW, the booster system is equipped with CR, CRE, CRI, CRIE pumps with motors with integrated frequency control. The total efficiency of the motor including the frequency converter is better than the IE3 level in IEC60034-31, even though this standard only applies to the motor.

- Hydro MPC-E maintains a constant pressure through continuous adjustment of the speed of the pumps.

- The system performance is adapted to the demand through cutting in/out the required number of pumps and through parallel control of the pumps in operation.

- Pump changeover is automatic and depends on load, time and fault.

The system consists of these parts:

Pump parts in contact with the pumped liquid are made of stainless steel EN DIN 1.4301 Pump bases and heads are of either cast iron/stainless steel (CRI) or cast iron EN-GJS-500-7 (CR), depending on pump type; other vital parts are made of stainless steel EN DIN 1.4301

The pumps are equipped with a service-friendly cartridge shaft seal, HQQE (SiC/SiC/EPDM)

- Two stainless steel manifolds to EN DIN 1.4571

- Stainless steel base frame to EN DIN 1.4301 up to CR 90; above CR 90 the pumps are placed on a galvanized I-Beam frame

- One non-return valve (POM) and two isolating valves for each pump

- Non-return valves are certified according to DVGW, isolating valves according to DIN and DVGW

- Adapter with isolating valve for connection of diaphragm tank

- Pressure gauge and pressure transmitter (analog output 4-20 mA)

- Control MPC in a steel cabinet, IP54, including main switch, all required fuses, motor protection, switching equipment and microprocessor-controlled CU 352.

More about this product

Pump operation is controlled by Control MPC with the following functions:

- Intelligent multipump controller, CU 352.

- Constant-pressure control through continuously variable adjustment of the speed of each individual pump.

- PID controller with adjustable PI parameters (Kp + Ti).

- Constant pressure at setpoint, independent of inlet pressure.

- Soft pressure build-up (To prevent water hammer during startup).

- On/off operation at low flow.

- Automatic cascade control of pumps for optimum efficiency.

- Selection of min. time between start/stop, automatic pump changeover and pump priority.

- Automatic pump test function to prevent idle pumps from seizing up.

- Possibility of standby pump allocation.

- Possibility of backup sensor (redundant primary sensor).

- Secondary sensor (Possible to switch to another sensor/setpoint).

- Multi-sensor (up to 6 sensors to influence the setpoint).

- Manual operation.

- Possibility of external setpoint influence.

- Log function.

- Setpoint ramp.

- Possibility of digital remote-control functions:

- System on/off.

- Max., min. or user-defined duty.

- Up to 6 alternative setpoints.

- Digital inputs and outputs can be configured individually.

- Pump and system monitoring functions:

- Minimum and maximum limits of current value.

- Inlet pressure.

- Non-return valve monitoring.

- Motor protection.

- Sensors and cables monitored for malfunction.

- Alarm log with the previous 24 warnings/alarms.

- Display and indication functions:

- Colour screen display.

- Green indicator light for operating indications and red indicator light for fault indications

- Potential-free changeover contacts for operation and fault.

- Grundfos bus communication.

-

manual PDFDownload

-

data sheet PDFDownload

Standard delivery:

Standard delivery is free for all orders except for some low cost/low margin items where standard delivery is £6.75. Some difficult to transport goods also have a varying carriage charge applied.

Please contact us for the estimated standard delivery times of the products that we have in stock, either by calling 01473 719950, or by dropping us an email at info@anglianpumping.com.

Deliveries will typically be made between 7am and 6pm, Monday to Friday (excluding public holidays).

Next day delivery:

Next working day delivery is available for a £15.00 + vat delivery charge.

Orders must be placed before 12 noon to qualify for next working day delivery. Orders placed after 12 noon on Thursday but before noon on Friday will be delivered the following Monday. Orders placed after 12 noon on Friday will be delivered on Tuesday.